Welcome to Roadlab

Rock Mechanics

We’re proud to introduce Roadlab Rock Mechanics, a state-of-the-art facility dedicated to the testing and analysis of rock and geological materials.

Our new lab combines expert knowledge with advanced equipment to deliver accurate, reliable results for the mining, geotechnical, civil, and construction industries.

X-Ray Diffraction | Uniaxial Compressive Strength | Point Load | Slake Durability

REACH OUT

A One-of-a-Kind Rock Laboratory in Africa

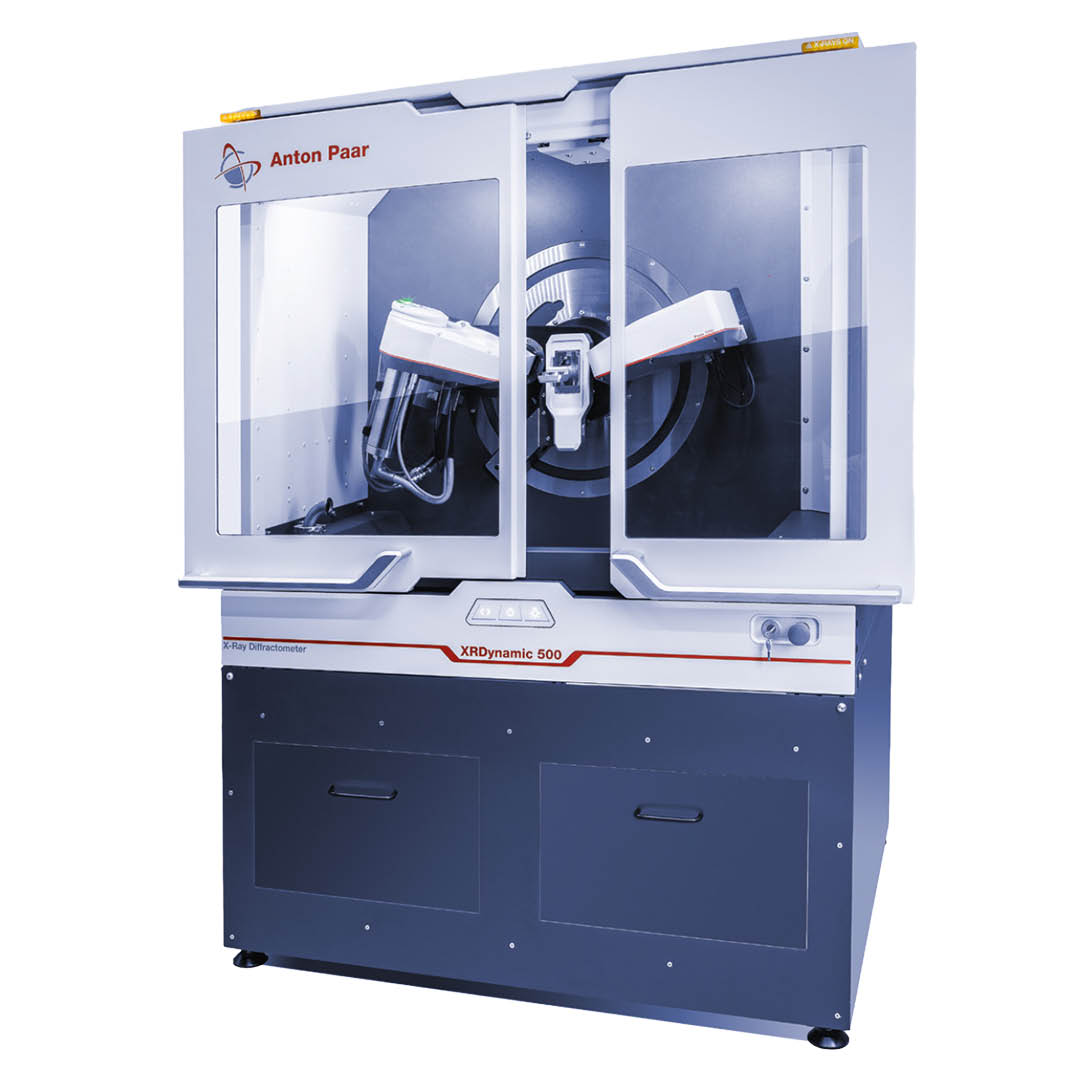

Roadlab Rock Mechanics is proud to operate the first X-Ray Diffraction (XRD) unit of it's kind in Africa.

This is the latest of our offerings supported by equipment produced by Anton Paar.

What this means for us - and our clients.

We now offer some of the most advanced mineral testing on the continent — high precision mineral identification and quantification for rock core analysis, soil characterisation and mineral exploration.

Supported by traditional soil investigations, this specialised facility offers unmatched insight into the materials used in mining, geotechnical design, pavement design and concrete works.

Advanced Analytical Services

Provides detailed insight into the composition, density, and structure of materials.

Durability & Performance Testing

Evaluates how materials withstand environmental stress, weathering, and long-term loading.

Core Testing Capabilities

Determines the strength and behaviour of rock and soil, forming the basis for reliable design.

Our Advanced Services

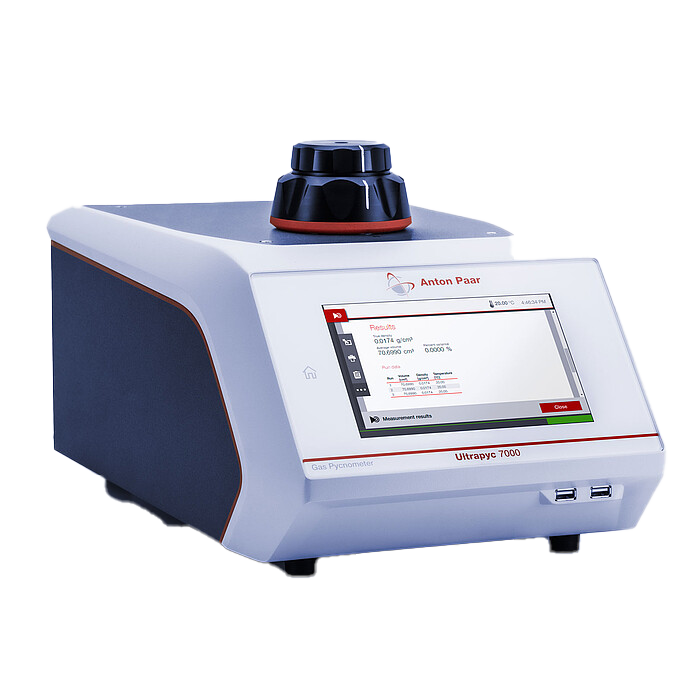

Roadlab Rock Mechanics was established to expand our analytical capability with advanced instruments such as the XRDynamic X-Ray Diffractometer (XRD) and Gas Pycnometer.

These systems reveal the mineral composition, density, and porosity of soils and rocks with exceptional precision — providing insights that go far beyond conventional testing.

By combining state-of-the-art technology with expert interpretation, Roadlab delivers a clearer understanding of material behaviour, durability, and performance, enabling engineers to design with greater confidence and control.

XRDynamic Xray Diffraction

Determines the mineral composition and crystalline structure of materials to near-atomic levels.

Specific Gravity (Gas Pycnometer)

Measures the volume of soil or rock specimens with exceptional precision.

Performance Testing

Understanding how materials will perform under real-world conditions is critical.

By simulating environmental and traffic stresses with durability and performance tests — including the Pinhole and Crumb Tests — we can assess erosion risk, skid resistance, and long-term weathering.

These services ensure that materials chosen for roads, structures, and foundations meet the highest standards of safety and resilience.

The results provide engineers with the data needed to predict lifespan, minimise maintenance, and ensure sustainable performance across all project conditions.

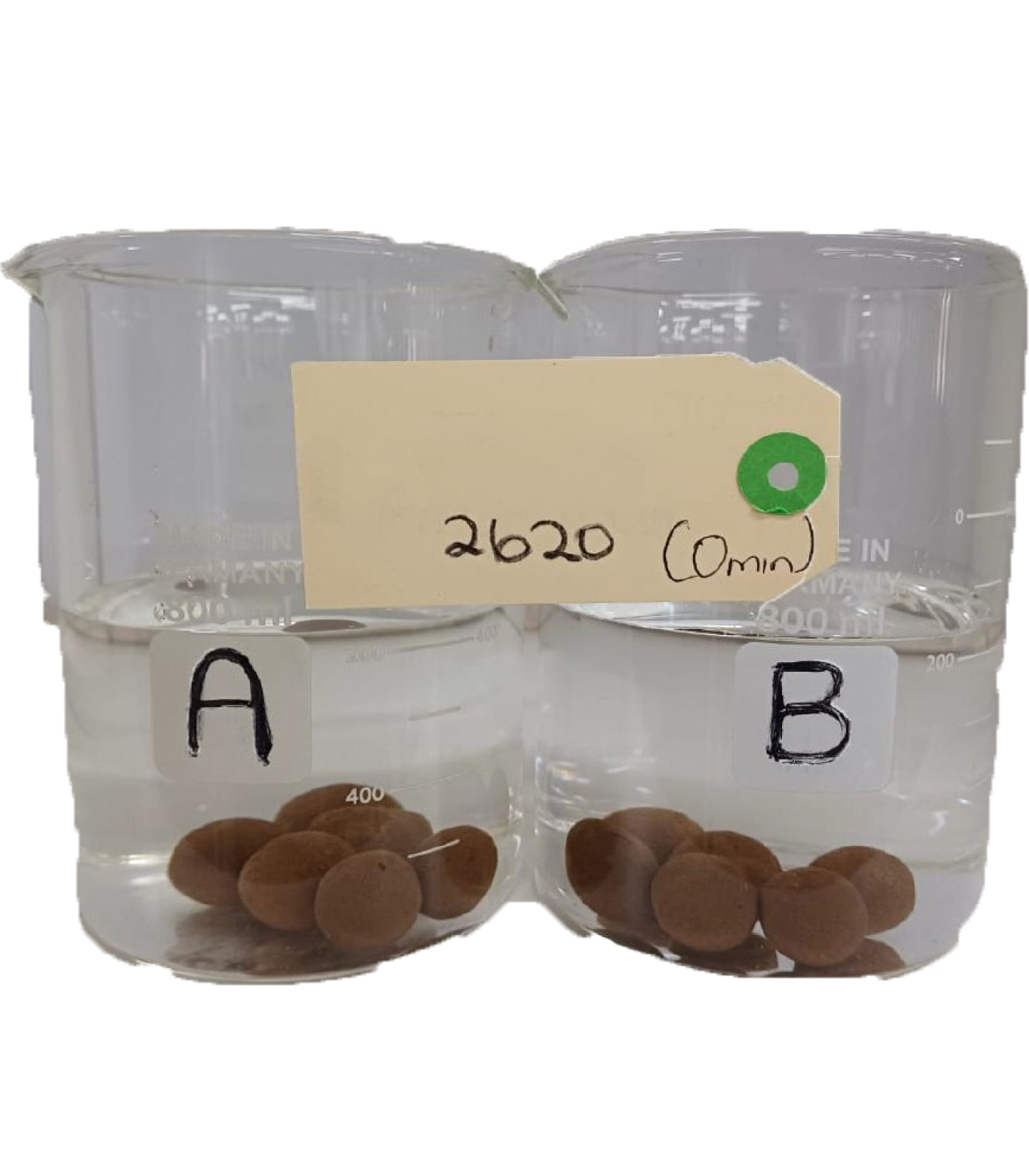

Pinhole Test

Evaluates the dispersive potential of clay soils under continuous water flow.

Crumb Test

Assesses the stability of clay aggregates and their resistance to water-induced erosion.

Polished Stone Value (PSV)

Measures the resistance of aggregates to polishing, ensuring safe skid resistance on road surfaces.

Core Testing Capabilities

Slake Durability Test

Measures a rock’s resistance to weakening and disintegration when exposed to moisture.

Point Load Test (PLT)

Determines rock strength quickly and cost-effectively, ideal for field or lab assessments.

Unconfined Compressive Strength (UCS)

Determines the maximum load a soil or rock specimen can withstand without lateral support.