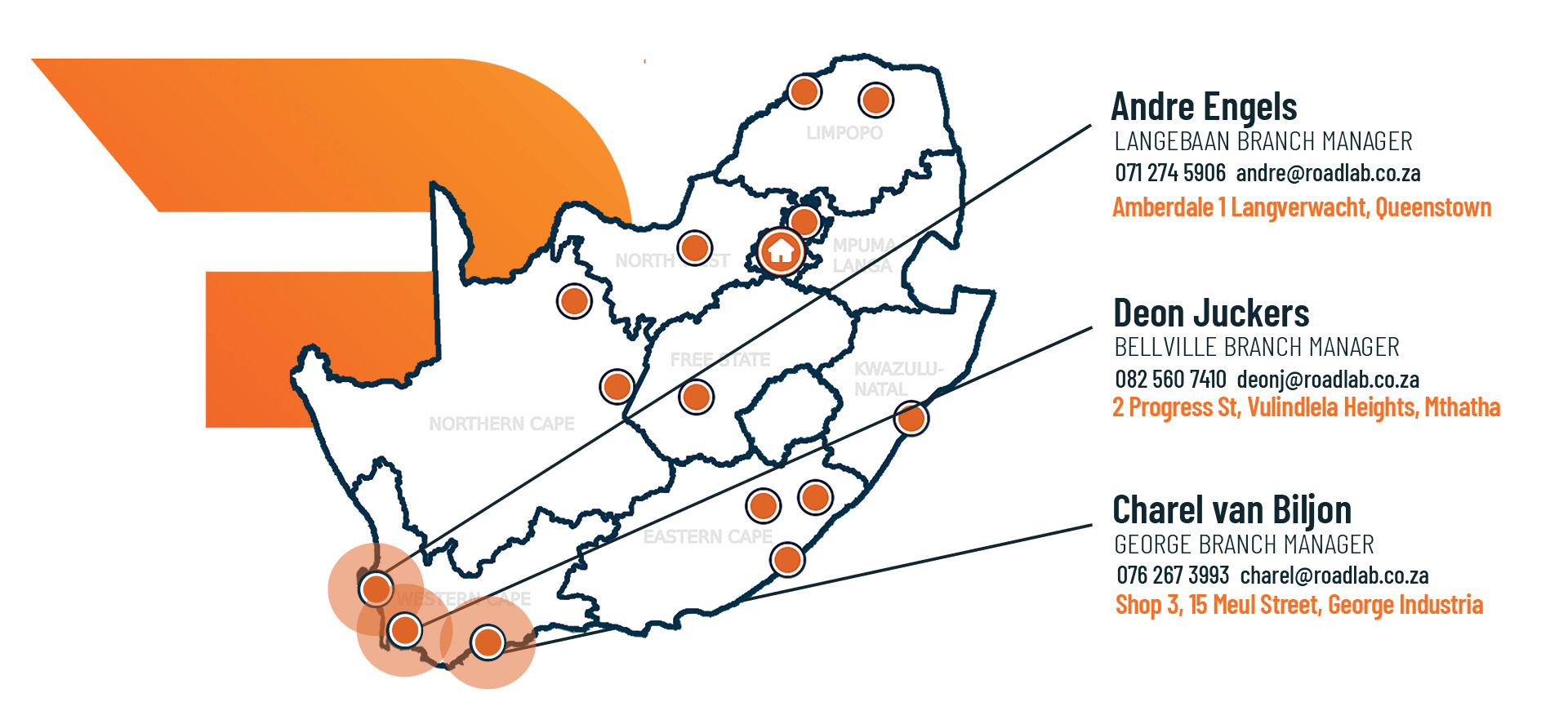

OUR PLACE IN

THE WESTERN CAPE

A trusted laboratory offering the Eastern Cape's broadest range of testing services, our accredited facilities are equipped to perform all your quality assurance testing.

YOU CAN REACH OUT TO OUR EASTERN CAPE TEAM TODAY AT 010 021 0570.

Supporting the Eastern Cape Construction Industry

ON-SITE AND LABORATORY TESTING

Leading Quality Assurance in the Western Cape

Our commercial branches in Bellville, George, and Langebaan deliver accredited soil, concrete, and asphalt testing for the Western Cape’s most important road, bridge, and construction projects.

We deliver infrastructure testing that meets the highest standards of precision, compliance, and reliability, enabling the new Amazon Africa Headquarters in Cape Town as well as local municipalities, engineers and road and construction companies across the great expanse of the Western Cape.

On-site Testing

Our on-site Testing teams in Bellville, George, and Langebaan carry out the full range of field services needed to keep projects on track.

Some tests — such as nuclear density testing, sand replacement testing, test pits, and soil sampling — are performed repeatedly across a site to build a complete and reliable picture of conditions.

Others, including plate load testing, Dynamic Cone Penetrometer (DCP) assessments, and Deep Probe Super Heavy (DPSH) testing, can provide valuable insights from only a few well-placed investigations.

In all cases, careful soil sampling practices are essential to protect the accuracy of the results later produced in our laboratories.

Supporting Municipal & Infrastructure Development

Roadlab works closely with the City of Cape Town and the municipalities of the West Coast District, Witzenberg, George, and Saldanha Bay to ensure infrastructure is built to last. Recent work includes Brackenfell Parking Area, Govan Mbeki Road and Jakes Gerwel Drive upgrades, Paarl Dal Josaphat Sport Stadium Parking, Sir Lowry’s Pass stability works, and Clanwilliam & Wolseley Dam water infrastructure improvements.

Soil Testing Laboratory

Testing such as the California Bearing Ratio (CBR), Unconfined Compressive Strength (UCS), and Indirect Tensile Strength (ITS) guide critical decisions in foundation design, road layer specification, and major construction planning.

Within the laboratory’s Plasticity Index (PI) section, specialists assess how soil will respond under varying moisture conditions with tests such as the shrinkage limit, liquid limit, plastic limit, and plasticity index.

These tests form the bulk of our commercial testing at construction sites served by our Cape Town, George and Langebaan laboratories.

Concrete Testing Laboratory

Our commerical concrete testing services give engineering teams the data they need to evaluate materials, understand site conditions, and improve a project’s likelihood of long-term success.

In the field, tests such as the slump test measure the consistency and workability of fresh concrete, ensuring it conforms to the approved mix design.

In the laboratory, analyses including compressive strength, flexural strength, and tensile strength testing provide critical data for designing safe and durable structures.

The preparation process — whether by coring concrete or moulding cubes — is essential to producing accurate, representative laboratory results.

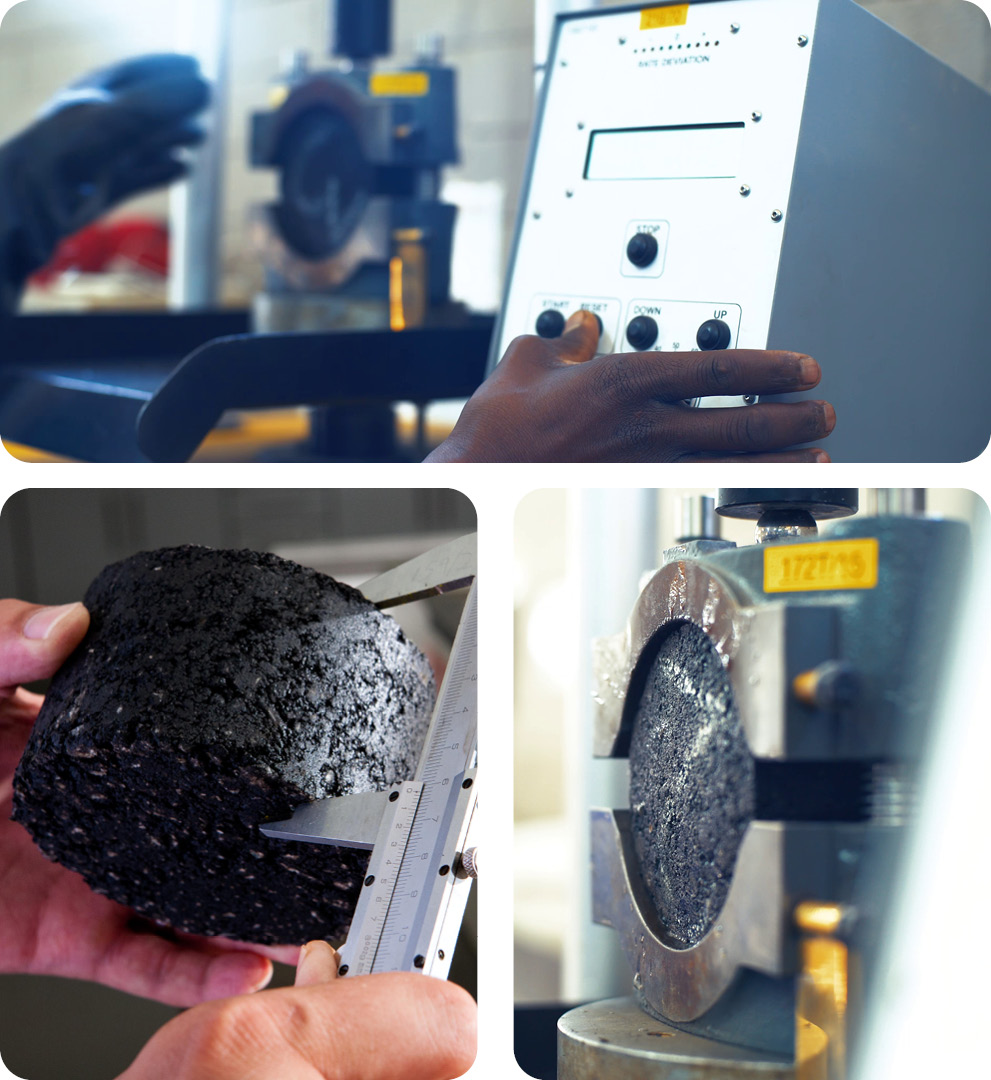

Asphalt Testing Laboratory

Our Asphalt Laboratory and field testing services provide the data needed to guide road construction, pavement management, and rehabilitation projects.

Core sampling and analysis evaluates the quality and consistency of asphalt layers in existing pavements, identifying potential defects or confirming compliance with design specifications.

Compaction testing measures density and void content to verify that asphalt layers have been compacted to deliver maximum strength and durability.

Marshall Stability and Flow testing assesses the material’s ability to withstand load and stress, ensuring the balance between strength and flexibility required for long-lasting pavement performance.

Oya Windfarm

Located between Matjiesfontein and Sutherland, the Oya Windfarm will produce over 590 GWh of clean energy annually from 32 Vestas 4.5 MW turbines. Roadlab is delivering on-site testing such as plate loads as well a range of laboratory services to ensure each foundation and platform meets design requirements.

Centreline Investigations

Centreline investigations involve a coordinated series of tests to evaluate the soil’s characteristics and suitability along a planned road alignment.

Nuclear density testing verifies soil compaction, Dynamic Cone Penetrometer (DCP) testing measures the in-situ strength of soil layers, and hand-dug test pits allow for direct observation and analysis of soil strata and site conditions.

Samples collected from these test pits are returned to our laboratory for further assessment, including moisture content, subgrade strength, and compressive strength testing.

These results provide engineers and construction teams with the data needed to design and build roads to specification.

Borrowpit Investigations

Borrowpit investigations are essential for determining the suitability of local soil and gravel for use in road construction.

A detailed Borrowpit Utilisation Plan ensures resources are extracted and used efficiently while minimising environmental impact.

Typical procedures include excavator test pits, Dynamic Cone Penetrometer (DCP) testing, Maximum Dry Density (MOD) testing, and California Bearing Ratio (CBR) testing — all carried out to confirm material quality and compliance with engineering standards.

The Southern Cape

In Hartenbos, our George branch is providing full On-site Testing, Soil Laboratory analysis, and Concrete Laboratory verification for the Garden Walk Mall development. In Mossel Bay, we are overseeing Asphalt Laboratory verification and durability assessments for the Maalgate Bridge upgrade, ensuring the structure and its connecting roads are built for long-term performance.

Our dedicated teams are ready to answer your questions. Reach out to us today!