OUR ROLE IN

NORTHERN CAPE INFRASTRUCTURE

The Northern Cape is experiencing an infrastructure surge driven by mining expansion and renewable energy development, all focused on the wealth of manganese, iron ore and zinc beneath the ground and the world-leading solar radiation above.

YOU CAN REACH OUT TO OUR NORTHERN CAPE TEAM TODAY AT 079 741 1244

Supporting the Northern Cape Construction Industry with

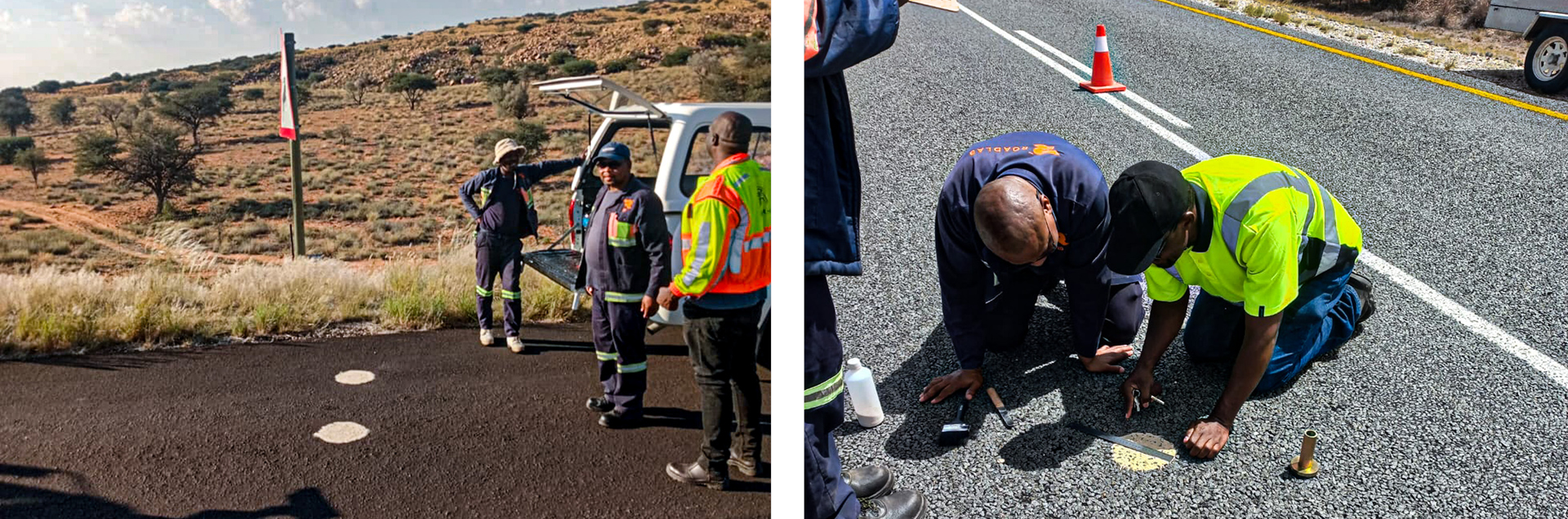

ON-SITE AND LAB TESTING

Above and Below: Power in the Northern Cape

The Northern Cape spans over 370,000 square kilometres — an area larger than Germany.

Beneath its surface lie vast reserves of high-grade manganese, iron ore and zinc. Above ground, its solar potential - or irradiance levels - are among the highest on the planet. Together, these factors position the province as a central pillar in South Africa’s mineral economy and clean energy transition.

The infrastructure of the Northern Cape is often immense in scale and in vision.

The rich ore deposits of the Northern Cape fuel some of South Africa’s largest mining operations.

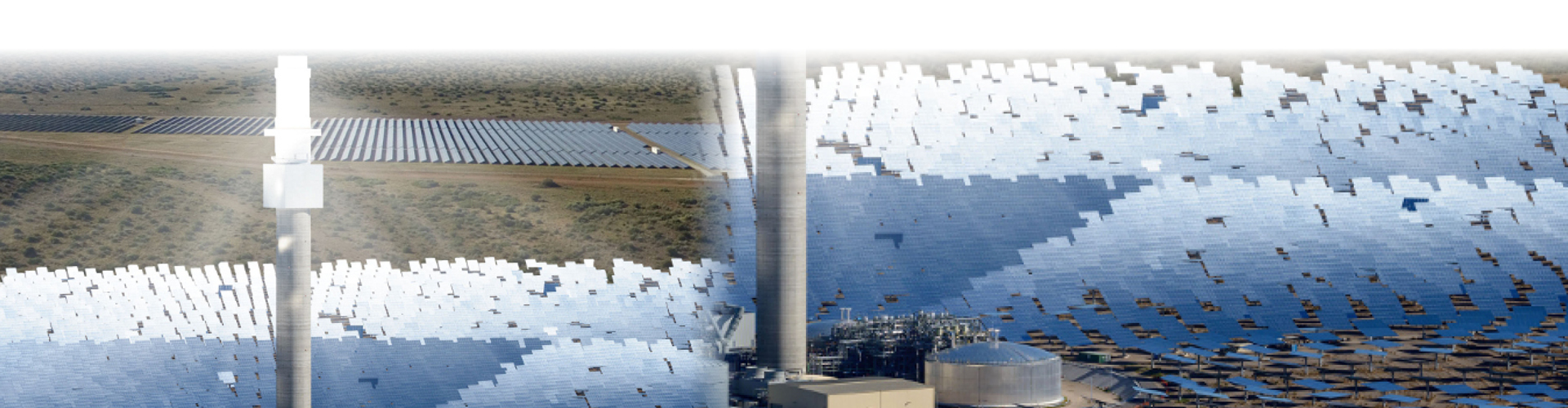

The largest energy investments in the country are Northern Cape renewable energy projects, like the R11 billion Redstone CSP Project and the 2-million-solar-panel Kenhardt Solar Power Complex Station.

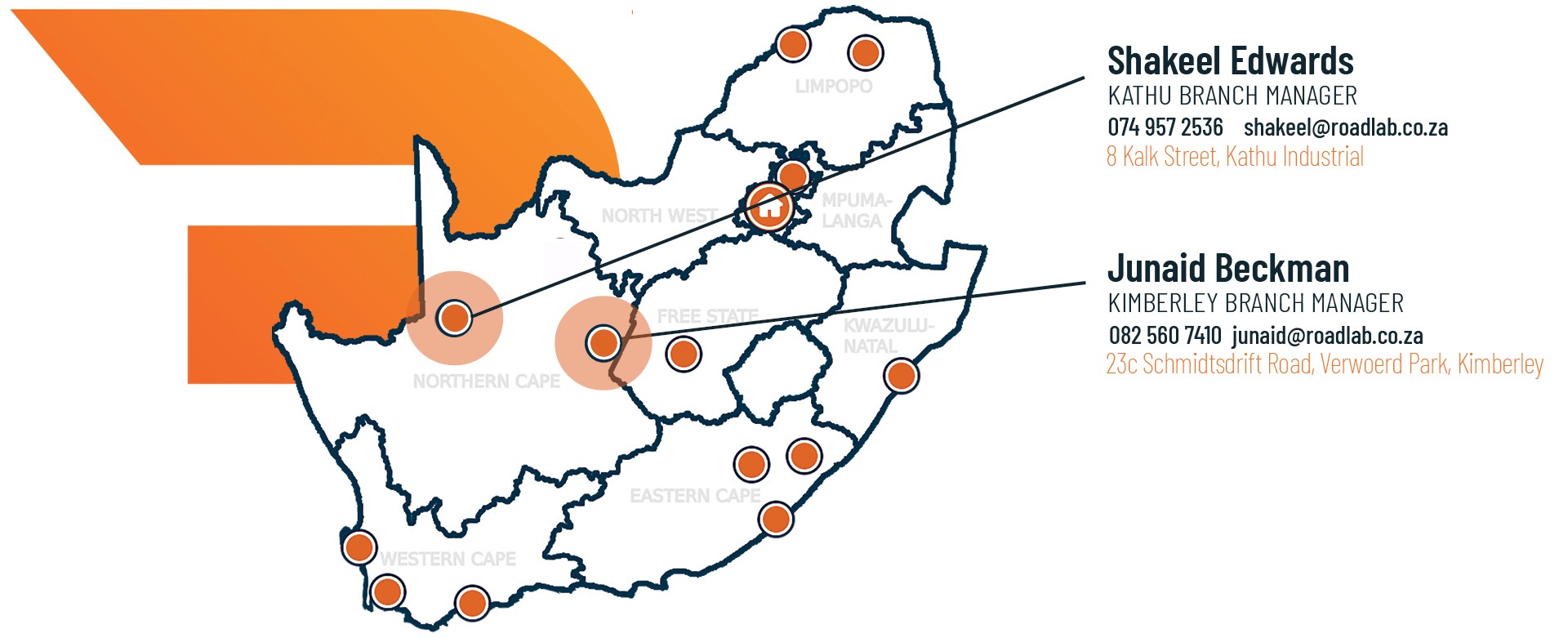

From our regional laboratories in Kathu and Kimberley, and with field teams operating across the province, Roadlab supports the materials testing requirements of mining contractors, solar developers, civil engineers, and road authorities building across some of South Africa’s most challenging terrain.

To meet these needs, Roadlab conducts a wide range of SANAS-accredited testing services, including Dynamic Cone Penetrometer (DCP) tests, plate load bearing tests, soil classification, CBR and compaction testing, concrete cube strength tests, on-site density testing, and Unconfined Compressive Strength (UCS) assessments. These services ensure that every haul road, solar platform, foundation, and pavement layer is constructed on a verified, durable base — ready to withstand time, traffic, and terrain.

Above: Solar Power

South Africa’s energy landscape is changing.

Near Kenhardt, over 500 MW of solar generation capacity (with more than 1,000 MWh of battery storage) is being constructed as part of the country’s most ambitious renewable energy project to date.

Further west, the Redstone Solar Thermal Power Project commenced commercial operations in June 2025, delivering 100 MW of continuous electricity through thermal storage technology — the first of its kind in the country.

Other projects are expanding access and diversifying generation across the provincial grid. These include projects Roadlab has supported such as the Rietkloof & Brandvalley Windfarms between Sutherland & Matjiesfontein, the Grootfontein Solar Farm and Boitshoko Solar Park near Groblershoop, and the Aggeneys and Springbok solar facilities.

Dynamic Cone Penetrometer (DCP) tests have supported early foundation investigations, helping identify suitable bearing layers and avoid costly remedial work.

We have provided plate load bearing tests to verify the strength and suitability of inverter and turbine pad foundations, helping developers minimise settlement risks and ensure structural integrity.

Soil classification, CBR, and compaction testing have been used to evaluate and optimise the performance of roads, access platforms, and turbine zones — critical for enabling equipment transport, site longevity, and daily operational safety.

To ensure that substations and structural elements meet durability and strength standards, we have conducted concrete cube strength tests and slump tests — confirming the quality and consistency of concrete used in the project.

Below: Mining

The mineral-rich corridors of the Northern Cape produce some of South Africa’s most valuable resources.

These include zinc, iron ore and manganese sourced from Aggeneys, Kathu, Postmasburg and Hotazel by Vedanta’s Gamsberg Zinc Mine, Khumani and Sishen iron ore mines and South32’s Mamatwan Mine.

On-site density tests and DCP testing have been used to verify the compaction quality and bearing capacity of haul roads, equipment platforms, and base layers for surface infrastructure.

Continuous sampling and classification of gravels, soils, and aggregates have guided the selection of materials for road and platform construction — helping clients meet specification and ensure consistency across large distances and multiple sites.

We’ve also conducted concrete cube testing for infrastructure elements and Unconfined Compressive Strength (UCS) tests on stabilised materials and select rock samples — providing data to inform both structural load capacity and suitability for use in high-traffic or high-stress zones.

Commitment to Quality: A SANAS-Accredited Facility

At Roadlab, quality is what we do.

This commitment to excellence shapes how we support infrastructure development across the Northern Cape — from remote mining platforms to large-scale renewable energy sites.

By continually refining our geotechnical, concrete, and materials testing processes, we help ensure that the province’s roads, foundations, solar bases, and haul routes are built to last.

Our work is underpinned by strict adherence to SANAS accreditation standards, ensuring that every test we perform meets national and international benchmarks for accuracy, reliability, and compliance.

From Kathu to Kimberley, Aggeneys to Kenhardt — Roadlab is proud to support South Africa’s most ambitious province with the trusted results it needs to build forward.

We're ready to answer your questions. Reach out below.